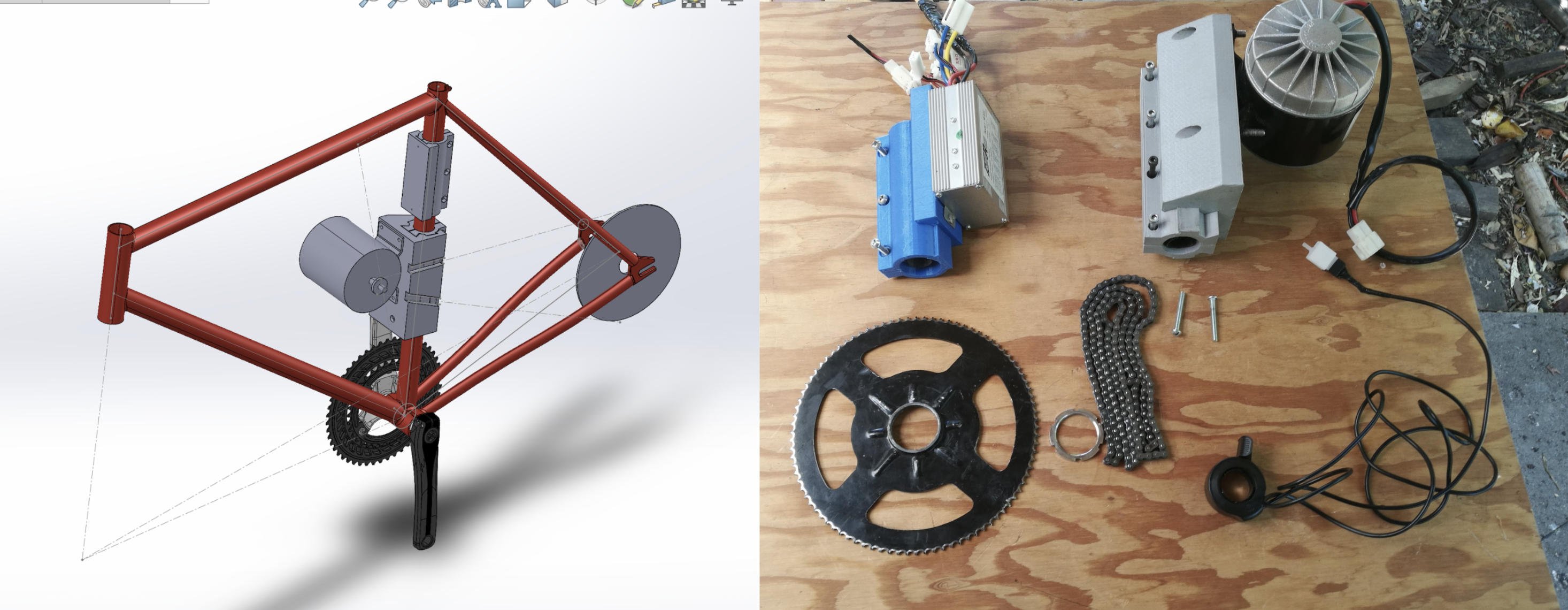

DIY Ebike Projects

June 2017-July 2018

I got tired of biking to school.

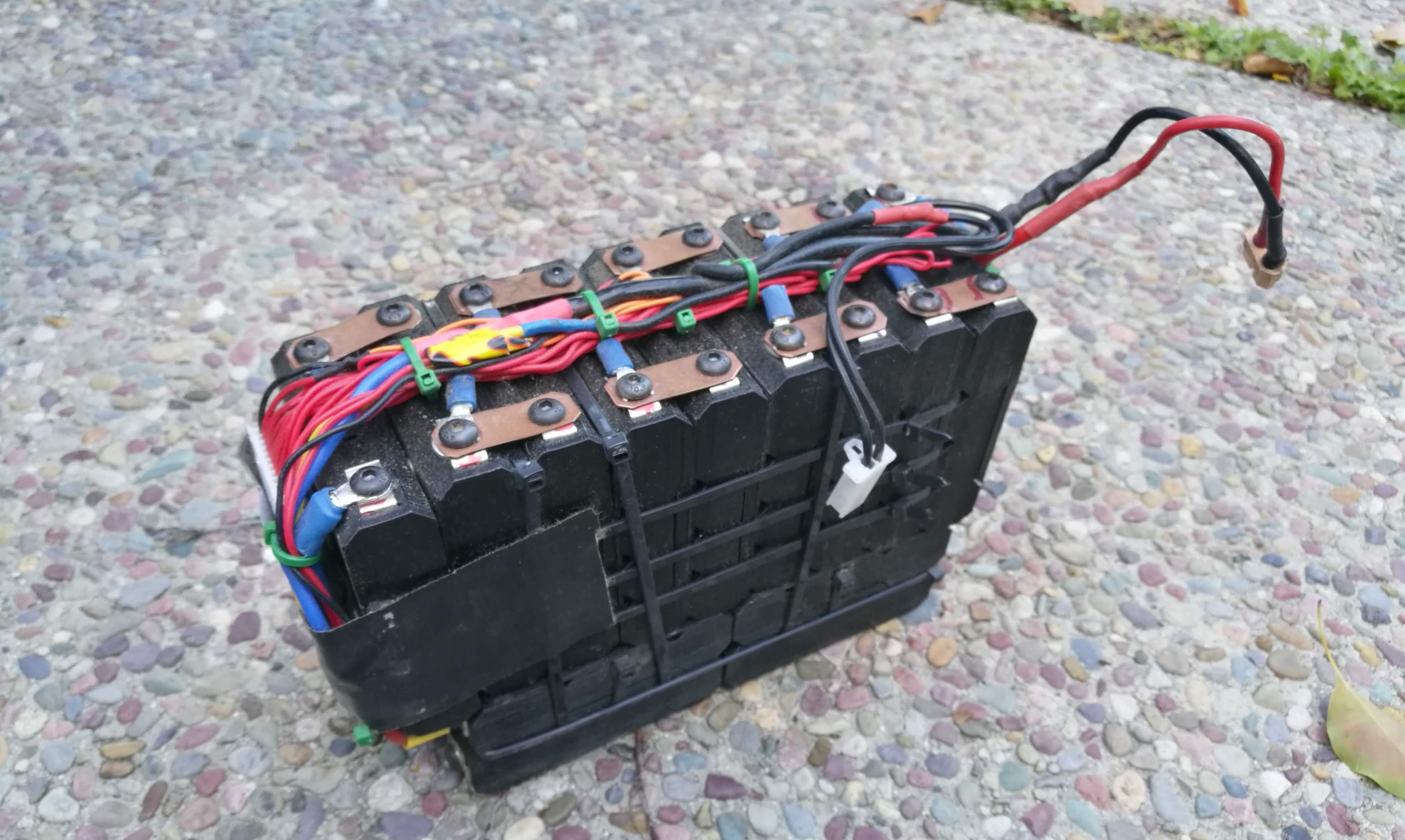

First I made a 3D printed ebike bike conversion which I made as cheap and easy to get working as possible. However once I got a taste of the effortless ebike experience — there was no turning back.