NU Formula SAE

Sept 2020 - Present

Formula SAE (FSAE) is a rigorous intercollegiate engineering design competition where teams from around the world build a formula one style race car from scratch over the course of 12 months.

Sept 2020 - Feb 2021

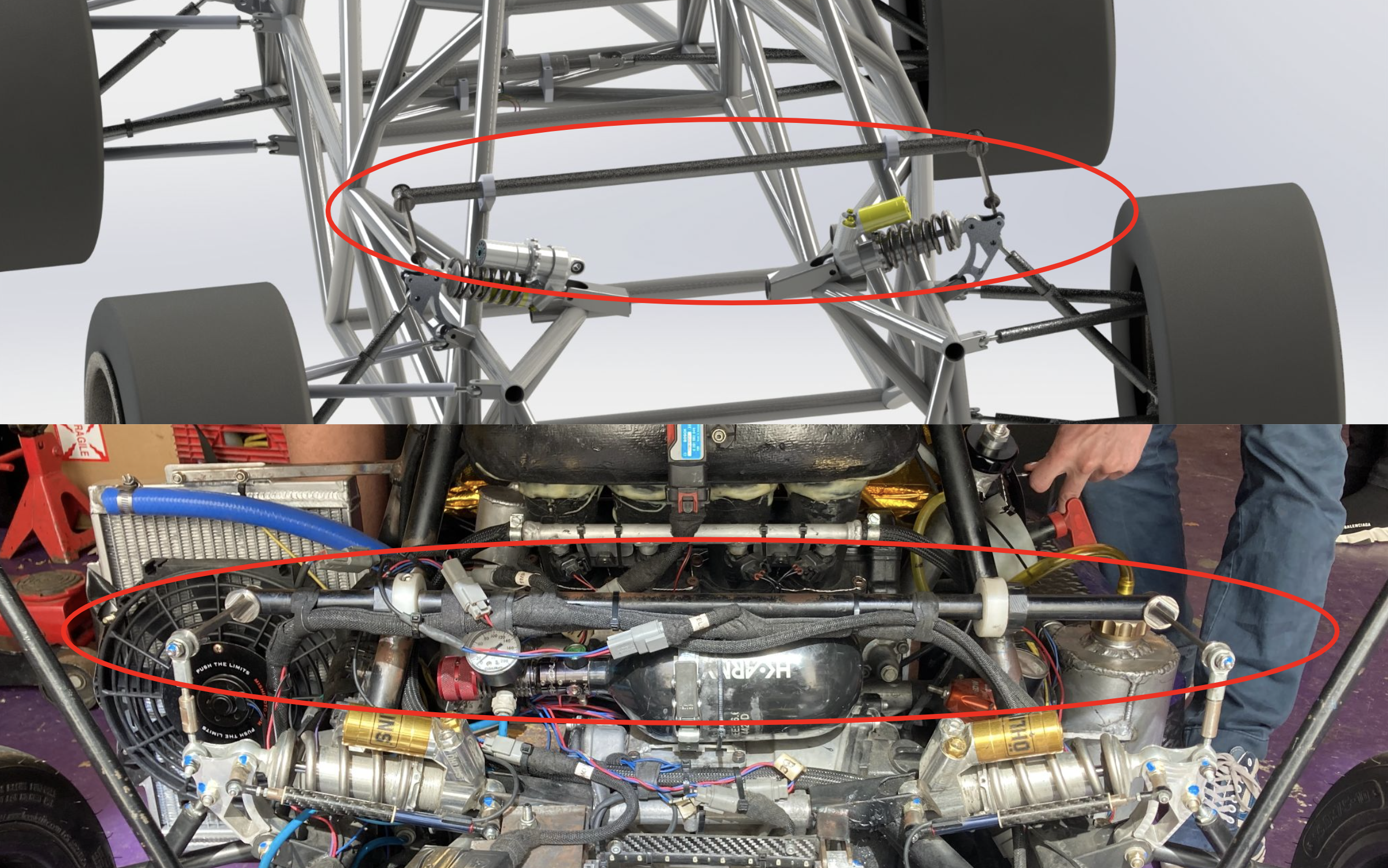

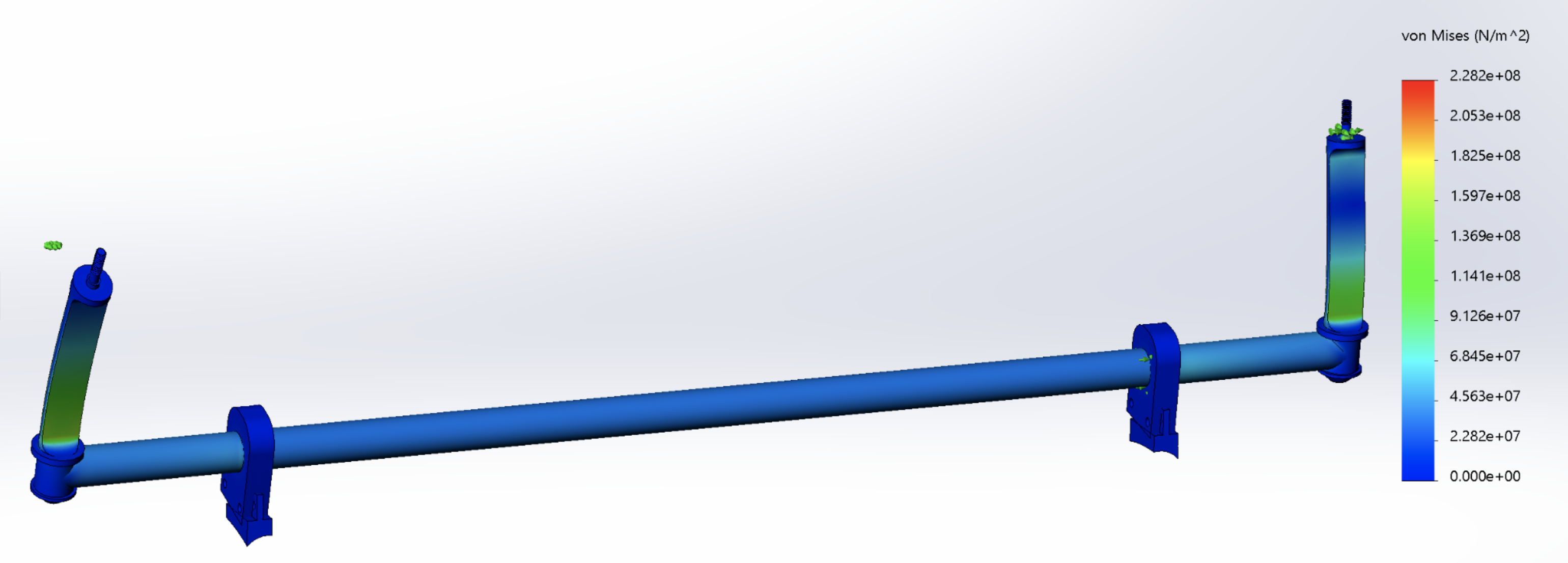

The anti-roll bar(ARB) is an element within our car’s suspension that joins the left side of the suspension to the right side thus limiting our car’s body roll when turning. My partner and I were given a target stiffness, range of motion, and desired stiffness adjustability range as targets to meet in our design.

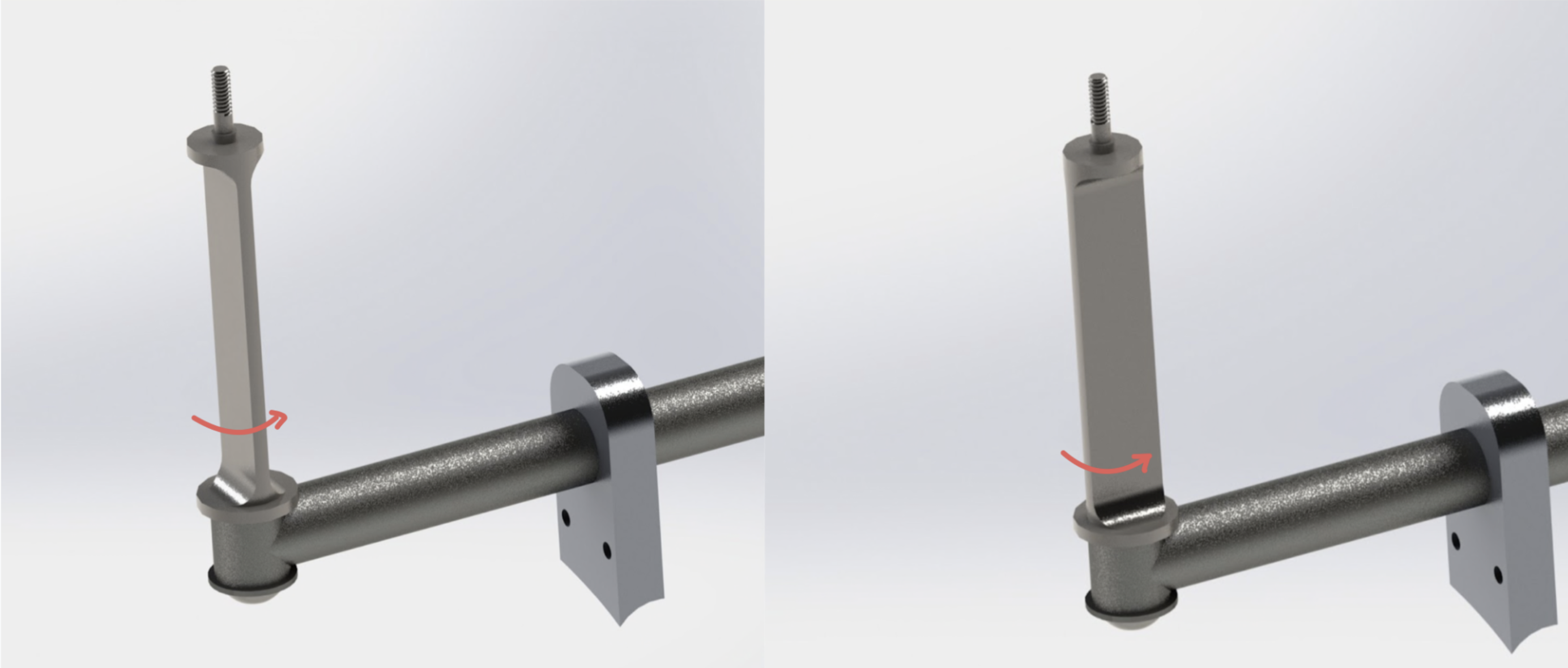

Our ARB has also has adjustable stiffness which can be changed by rotating the orientation of the blades thus changing the distance to the neutral bending axis.

Since the general form of ARBs in the automotive industry are well flushed out, we decided to follow the same overall architecture as most conventional ARBs which consists of two blades joined by a torsion rod. Our main goal was to optimize weight savings from last year as much as possible. To achieve this we chose to use titanium 6Al 4V Grade 5 because of its high elastic modulus to density ratio and availability from our sponsor.

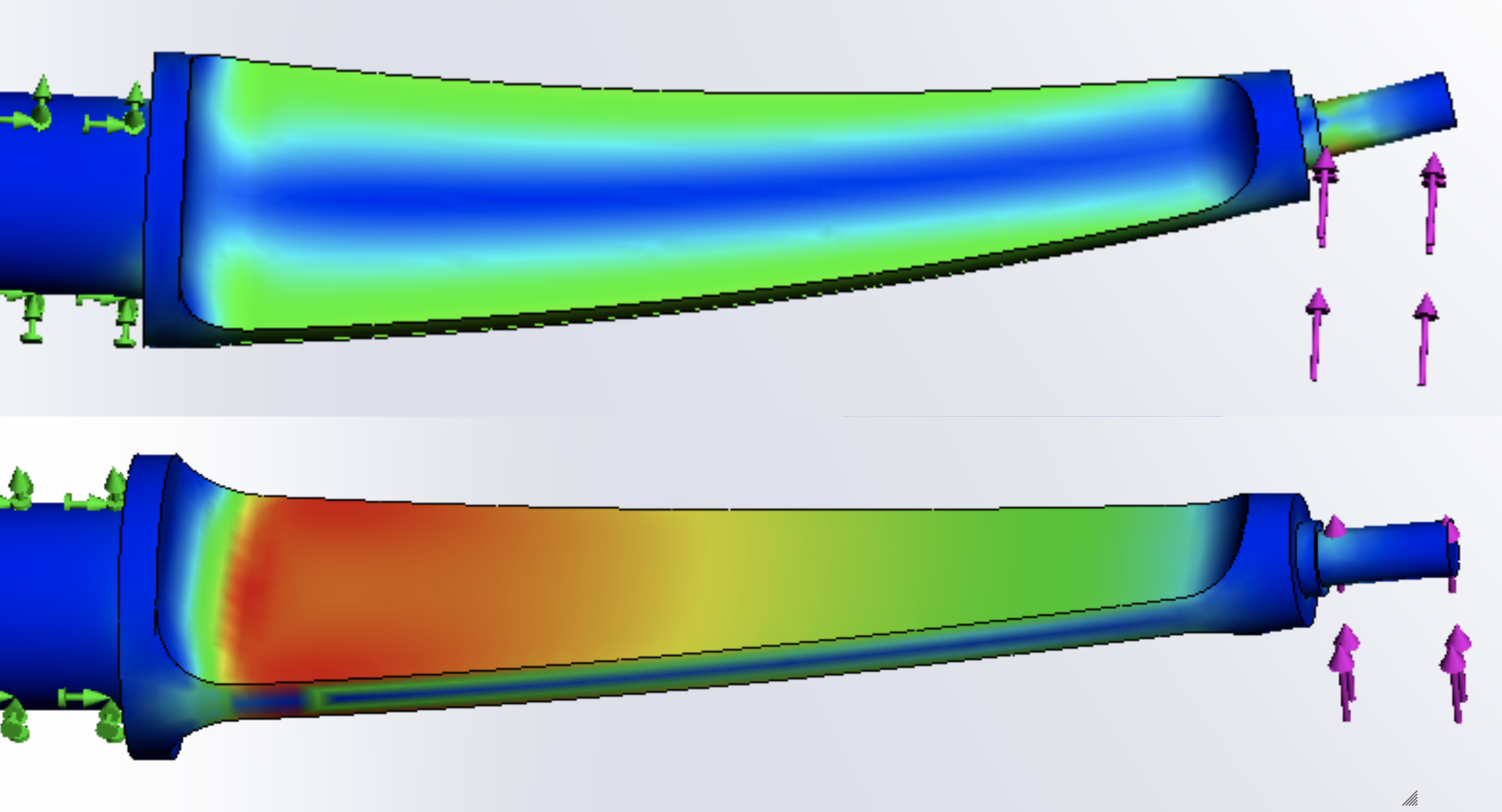

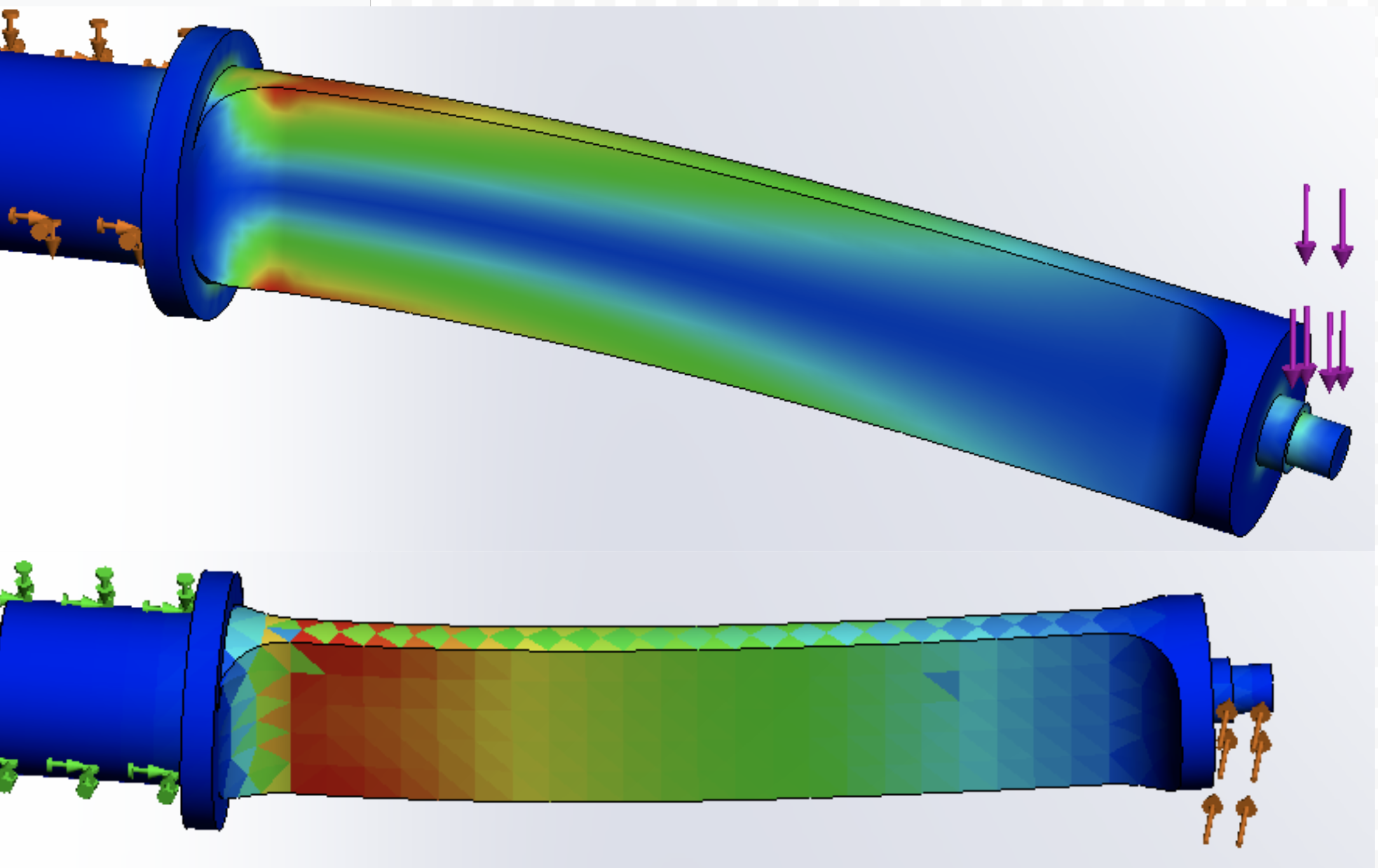

Next, we investigated tapering the ends of the blades inwards. To calculate the stiffness of the tapered blade we approximated it as a trapezoidal prism. Since the range of motion is not very large, we approximate the area of the moment of inertia as constant. These calculations were then repeated for both the stiff and nonstiff orientations.

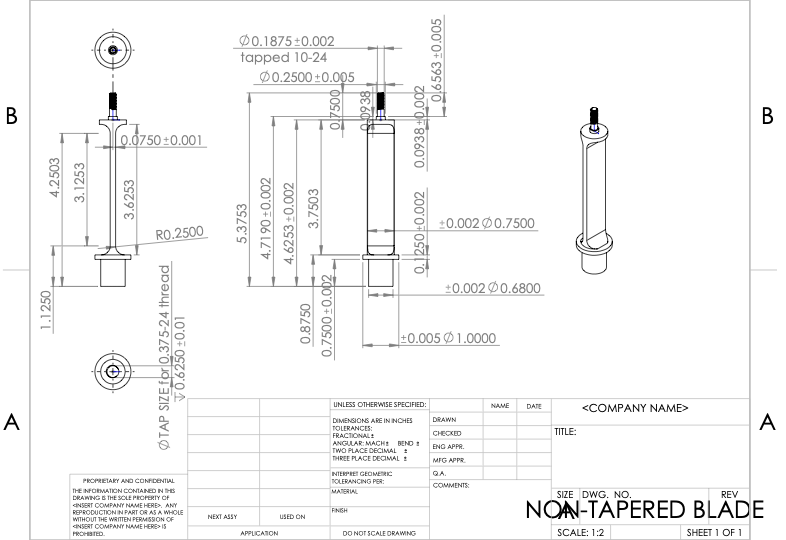

From this we found an optimal geometry and put our ideas into CAD but as a contingency in case of a critical error we also designed a non-tapered blade. After running the FEA simulations and doing some final tuning, we found the weight savings from the tapered blades are negligible. We decided that it was not worth it since machining tapers is non-trivial.

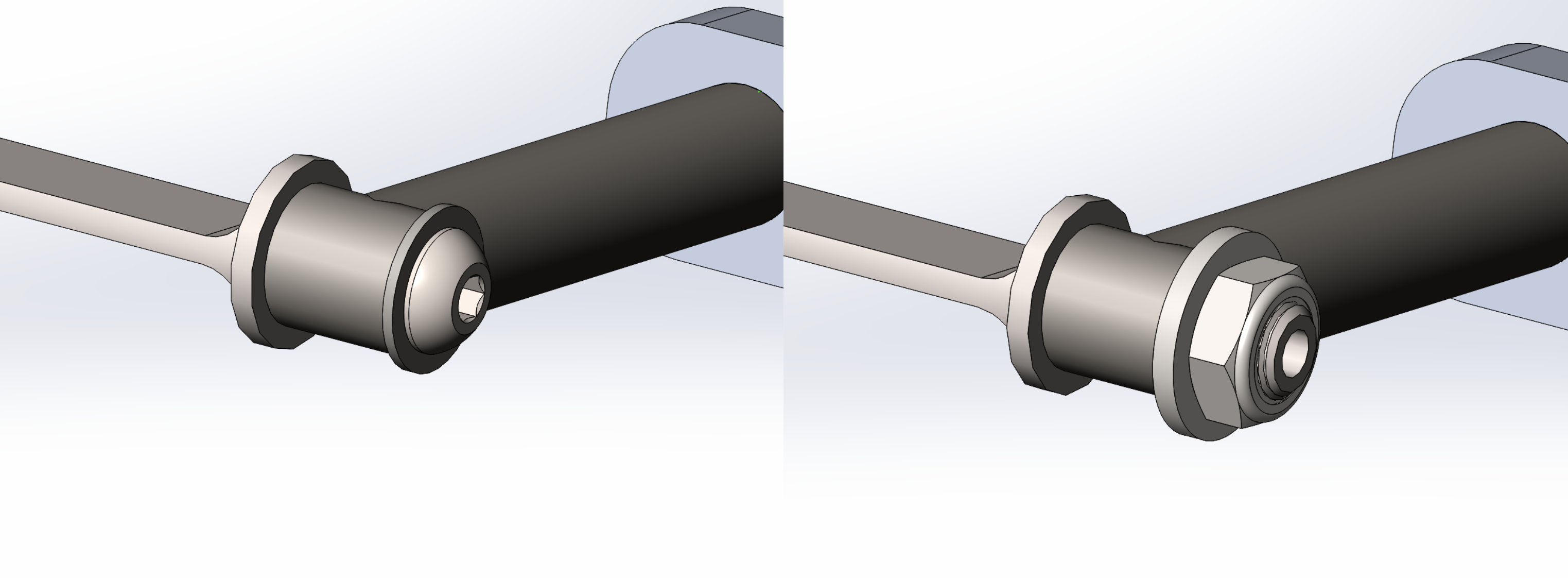

Previous year’s design used a large nut and externally threaded boss to secure the blade to the torsion rod. To save on weight we changed it to an end tapped button head and bored out the center of the base.

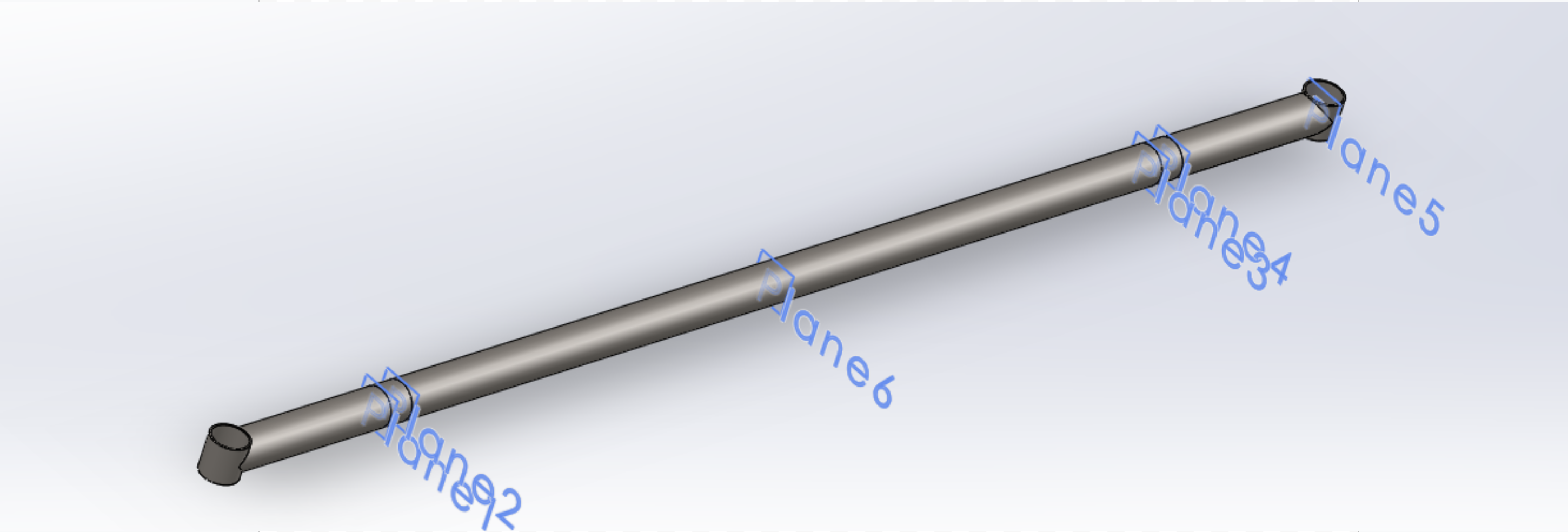

We chose 4130 steel for the torsion rod because of its abundance, and availability in tubular forms. We were able to achieve more weight savings by thinning out the walls of the torsion rod and increasing the diameter while maintaining the same rotational stiffness.

With all the parts together we can approximate the entire ARB system as three springs in series to get our final stiffness.

The blade was the most complex part to make and involved turning multiple features in a rod of titanium round stock on a manual lathe. Making the blank features was straight forward and was done according to the engineering drawings I made.

The challenging part was machining the flats in the blade. To do this we used two collet blocks to hold both ends and then clamped one end down against the mill table.